capabilities

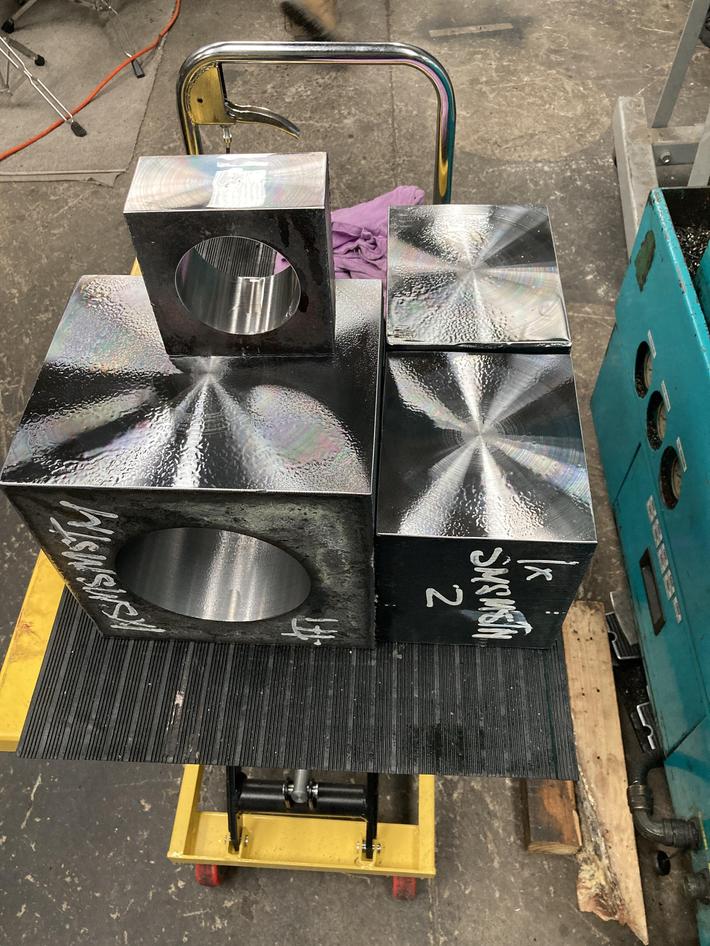

MCH has the capability to assist customers with the design and manufacturing process from start to finish. Using our industry experience and engineering knowledge, we are able to design and manufacture solid and sheetmetal components to suit the customers requirements using the latest CAD/CAM software and manufacturing machinery.

We currently specialise in low volume work and provide short turnaround times for our customers with a focus on quality. We can also perform small batch runs when required.